IT’S FRIDAY NIGHT AT ORD PIZZERIA ON Montrose near Ashland, and pizzas are spinning. They’re being tossed to reach their full width, they’re being spun onto paddles for transfer, they’re being twirled in the oven for even browning—and they’re riding around on the oven’s rotating shelves, like a 500 degree ferris wheel.

ORD, named of course for O’Hare’s airport code, is in many ways a modern pizza place for Chicago. The pizza style isn’t any of the typical Chicago styles, but what’s usually called New York pizza, that is to say, dough kneaded and then refrigerated for at least 18 hours and up to 3 days to develop flavor, then hand-tossed to promote a light, bubbly texture. (Traditional Chicago pizza crusts are often rolled out like pie crust, which breaks the bubbles.)

The toppings include all the standard things you expect—pepperoni, mushrooms, etc.—but the menu also includes a dozen specialty pies of unusual but well-balanced toppings, like the Colt, with roasted chicken, bacon, garlic, Cremini mushrooms and crushed tomatoes, or the Rose, which has roasted potatoes, garlic, caramelized onions, corn, arugula and fontina cheese, brushed with olive oil. “One thing I tried to do was straddle the fine line of safety and pushing people slightly outside their element,” says owner Daniel Bridge, and he seems to have been successful—the meatless Rose is the #1 seller of the specialty pizzas.

ORD Pizzeria owner Daniel Bridge

The exception to all this modernity is standing right in front of his kitchen crew, and visible to anyone who walks up to the counter: the squat, massive oven, about 10 by 10 feet square, with its brand name—Faulds— baked into the enamel in a typeface that goes with tailfins and fedora hats. The landlord told Bridge that it’s been in the space for at least 30 years, but if that’s all, somehow the behemoth was moved at least once, because a plate says it was made in 1963.

You might have expected a modern pizza maker to have replaced an old warhorse like this with something newer and more up-to-date. In fact, Bridge is one of a number of local pizzeria owners who treasure their Faulds ovens, made in Chicago through most of the middle of the last century. And the story of how he found it and brought it back to life is fairly epic, as starting-a-pizzeria stories go. But Bridge wouldn’t have done it any other way: “I won’t find an oven that does its part better. I might find something that’s smaller and faster and more efficient, I might learn to make pizzas better myself, but I’ll never find anything that cooks pizza better than this thing does.”

DANIEL BRIDGE IS A TALL, TRIM TEXAN WITH A SHAVED HEAD and good Southern manners (anyone he references, like a service technician, is “a gentleman who…”). A lifelong restaurant guy, he also has a dry wit about the coals-to-Newcastle aspect of launching a pizzeria in Chicago.

His first job at 17 was delivering pizza, and he worked in Houston for the Pappas restaurant group before coming here to help their Cajun concept, Pappadeaux’s, in Arlington Heights in the 90s. After that he helped his brother open a couple of pizzerias in Houston—”Working with my brother and working for the first time on an owner level, gave me that final dose of confidence in the areas of owning a business rather than just being a chef,” he says.

So why pizza here? “That’s a great question. If we look at it from the obvious stupidity of ‘why pizza’…” he laughs. “When I opened this restaurant, I had four or five legitimate food concepts that I felt were ready to go. For many years, I wanted to do Texas barbecue. But I had to do something that I could achieve in a small space. Something I’d observed with my brother’s operation is that pizza is one of those things that we can sell outside of our four walls. Square footage becomes less of a factor at that point,” when you have delivery business.

Two more things led him in this direction. The first was that, for all that Chicago is a famous pizza town, he felt that much local pizza just wasn’t really very good. “In a city like Chicago, or New York, where we rave about our pizza credentials, any individual isn’t any smarter than anybody in Des Moines or wherever. They’re falsely propping themselves up on something that’s not worth it. I mean, the majority of deep dish pizza in Chicago—I’m sorry, but it sucks,” he says.

The technician said, “This thing’s about to fall apart. I won’t work on this thing, because it will kill me. The only way I’ll go near this thing is if you restore it.”

Another bunch of customers chased away, no doubt, but hear him out. “I thought, if we could just do pizza better, you’ve got a tremendous market, you’ve got a tremendous opportunity. I’m not crazy for trying to do pizza in a pizza city, I’m just trying to do it a little different and a little bit better. There was some tactical strategy to it, even though, two and a half years later, it still seems suicidal,” he laughs. Kind of.

Fresh herbs added after baking

The other thing that attracted him to pizza… well, you’ve already met it. “I had become indirectly familiar with these ovens just as a customer at pizzerias in Chicago—‘What is that thing?’” Bridge says. Faulds ovens still exist, and are often showpieces, at a number of old school-leaning pizzerias all over the city. As Rich Jensen of Pizza Castle once told me, the ovens are not only prized, but when an old one hits the market, owners race to buy it for the spare parts. That’s because, when you have a 50+-year-old oven, it’s going to take some work keeping it going. As Daniel Bridge was about to find out.

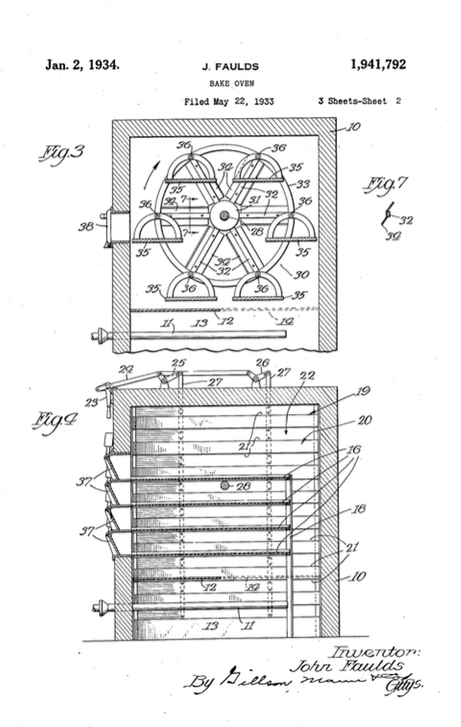

BORN IN SCOTLAND IN 1871, JOHN FAULDS of Oak Park, Illinois seems to have made commercial bakery ovens his life’s work—as early as 1900, when he was still listed as “a citizen of the United Kingdom of Great Britain,” he appears on a patent document for an oven, using hollow tiles to distribute heat more evenly, for his employer, a company called Middleby-Marshall. (They too would come to make rotating ovens—you can see one of theirs at Phil’s Pizza in Oak Lawn—and still exist as a maker of conveyor belt pizza ovens based in Elgin.)

Over time Faulds would come to focus on the question of how to squeeze more capacity into the floor space an oven occupied—the obvious limitation being that an oven could only be as deep as a baker could comfortably reach inside, so a bigger oven was, by necessity, a wider oven. His initial solution was to stack a series of shelves inside the oven which spun like a lazy susan, so it could be twice as deep but you could spin it around to reach what you wanted. On August 15, 1928 Faulds applied for a patent for this design, which was granted as Patent No. 1,771,885 on July 29, 1930.

A 1934 patent document showing John Faulds’ rotating shelves

In 1932 he launched Faulds Oven & Equipment Co. near Pulaski and Diversey, and two years after that he patented an oven with a ferris wheel design in the middle and stationary shelves on either side. It was another 15 years before he filed an application for a fully rotating-shelves gas oven on December 2, 1949. He was granted Patent No. 2,650,554 on September 1, 1953—as it happens, two years after his death at age 80, by which time his son was running the company. If you see one in use, it’s likely to be this design, with full-width shelves of quarter-inch steel.

I’ve been calling it a pizza oven, but of course the word “pizza” appears nowhere in the patent documents, which cite the usefulness of the oven design for cakes, pies, and even roast turkeys. (Plenty of barbecue joints today smoke meat in a cooker with a similar rotating design.) Pizza in some form in Chicago is thought to have predated Pizzeria Uno in 1943, but it would hardly have been the first use to come to mind. Faulds’ oven was really a bakery oven, with six shelves of 1/4″ thick steel, sized so they would exactly accommodate three standard 18″ by 26″ sheet pans, suitable for mass production of pastries or breads.

After coming back from his service in World War II, John Faulds Jr. took over his father’s business. Thanks to G.I.s like John Jr. (though not him—he was stationed in the Aleutians), an Italian discovery called pizza became popular in postwar America. With the addition of that new category to sell to, the oven business was good—at least as long as the gas ovens didn’t blow up.

Which happened on March 6, 1955, at a Wieboldt’s store in River Forest. While installing a new oven for baked goods, the Faulds technicians relied on the Wieboldt’s personnel’s assurance that an old line had been shut off and capped. In fact it filled a crawl space with gas, and when the oven was lit, it exploded, killing four employees of Faulds Oven (a fifth of the staff) and one Wieboldt’s engineer.

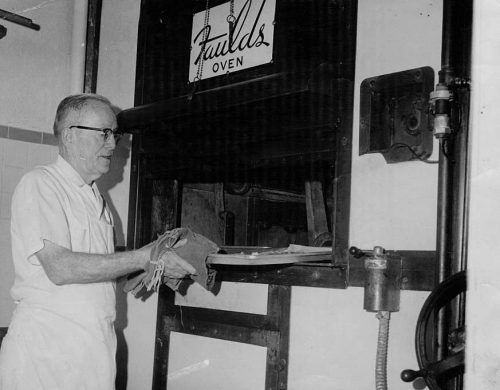

A Faulds oven in an Indiana hotel, 1950s. Note hand crank at right, in case you want to quickly get to a shelf

Despite the headlines, through the 1950s and 1960s Faulds ovens were a popular choice for pizzerias, not only in Chicago but throughout the upper midwest and beyond. There seem to be a number of them in Florida (Chicago emigres?), and in Seattle there’s a place called Delfino’s Chicago-Style Pizza, the name justified by their Chicago-style Faulds oven.

But like a lot of small manufacturing concerns, Faulds seems to have found it hard to weather the economy of the late 60s and early 70s. A manufacturer’s directory suggests that John Faulds Jr. sold part or all of the company around 1969, because suddenly one Maxwell Brace III is listed as the president and Faulds has the (somewhat honorary-sounding) title of Sales and Engineering Manager. The plant manager by then is one David Moskal, and by the late 70s Moskal is listed as the president and the address has changed to north Kedzie.

I don’t know when they stopped making ovens—all I can say is, I’ve never seen one in early 70s colors, or anything besides that postwar black and white—but by the 1980s Moskal was running what was left of it as a parts supplier from a small warehouse on Clybourn. He died in 2009, and John Faulds Jr. died in Florida in 2012. (Maybe he was the one who sold all those Florida ovens.) Moskal’s remaining parts inventory went to Cobblestone Ovens, in Elk Grove.

Which is who you call now if, like Daniel Bridge, you have a Faulds oven in need of serious attention.

WHEN BRIDGE FIRST SAW THE SPACE AT 1607 W. Montrose, it wasn’t a pizzeria—it was a Mexican bakery that had closed, pretty suddenly by the looks of it. “It looked like one of those things where the marshal’s at the front door and they’re going out the back,” he says. “The previous occupant just took off—there was uneaten food sitting on the counter.”

But as much cleaning as Bridge would have to do, the condition of the restaurant paled next to the condition of the oven, hidden from customers by a partition which Bridge tore out. He called a gentleman who was a technician to take a look at it, and his response was pretty blunt: “He said, ‘This thing’s about to fall apart. I won’t work on this thing, because it will kill me. The only way I’ll go near this thing is if you restore it.'”

Inside the “ferris wheel”

Bridge explains, “The oven had not been maintained, so there was literal wearing of metal on parts where there’s a lot of friction created. But the wearing occurred after the original parts to prevent wearing, i.e. bearings, were long gone. So you had a shaft, supporting a bearing that was maybe three inches in diameter, that went into a hole that was three inches in diameter– and that bearing is gone, and instead you had a one inch post that’s just rolling around in there, supporting the weight of this hundreds of pounds of steel deck.”

He could have torn the oven out and scrapped it for newer ovens, but he’d have been left with a 10 by 10 foot hole in the kitchen, requiring new floor and reconfiguring his work flow (since a smaller oven would have been further from the prep area). And more than that, he had used the oven for test pizzas, and liked the results. “I couldn’t have been happier. Those test pizzas came out so beautiful, and the bottom color and the texture was just what I was hoping for.”

Faulds ovens are a very small part of Cobblestone’s business by now, but they had what Bridge describes as a “70-year-old technician” who knew them inside out—literally. To repair the oven, the enormously heavy steel shelves had to be removed one by one, carefully braced on metal pipes so they didn’t fall, and then a repairman had to climb inside the massive oven and install the custom-machined parts from the inside. Finally, the shelves were reinstalled, one by one.

Bridge seems to have no doubt that restoring his slice of Chicago history was worth the effort, not only to rebuild it but to understand its personality.

“Forgive my language, but it’s a badass oven,” he says. “And you feel kind of badass when manning it. When you’ve got six decks, and fifteen tickets and thirty pies in that thing, you’re a real cook at that moment. For an old guy who’s owning a business and getting further and further away from being a cook, I couldn’t be in a better position today. Because I’m as much of a cook as when I was 17 years old, and I get the same thrill out of it.”

EPILOGUE: ORD Pizza has closed, but the location was taken over by Crushed Pizzeria, which continues to use the vintage Faulds oven.

Known Faulds Oven Locations in Chicagoland (Updated 10/3/24)

I’ve received many emails about Faulds ovens since this piece went up in 2016. Here’s the current state of my Faulds location knowledge

Crushed Pizzeria (former ORD location)

Cookies and Carnitas (Edgewater; closed)

John’s Pizzeria (Logan Square; closed)

Yaya Mas (former Amato’s; not sure if it is still in use there)

Bella Luna Bar & Pizza (Near North Side)

Pat’s Pizzeria (Printer’s Row)

Cafe Colao (Humboldt Park)

Victor’s Pizzeria (Austin)

Angelo’s Wine Bar (Albany Park)

Sano’s Pizza (Albany Park; closed)

Godfather’s Pizza (Uptown; closed)

Punky’s Pizza (Bridgeport)

Dino’s Pizza (Norwood Park)

L&L Pizzeria (McKinley Park)

Pizza Castle (Marquette Park)

Gianna’s Chicago Pizzeria (Calumet Heights)

Villa Palermo (West Rogers Park)

Coletti’s (Jefferson Park)

Larsa’s Restaurant (Skokie)

Italian Bakery (Addison)

Kim’s Uncle Pizza (Westmont)

Giuseppe’s Pizza (Des Plaines, closed)

Lilac Bakery (Lombard)

Hi-Way Bakery (Crete)

Barnaby’s (Northbrook)

Albano’s Pizzeria (Cicero)

Barone’s (Brookfield)

Capri’s (Rockford)

Delfino’s (Seattle)

Doyle’s Restaurant (Houston; closed)

There are no doubt many more, as well as many in bakeries, where you can’t see them. If you know of one, please send it to [email protected]

Michael Gebert goes around and around as editor of Fooditor.

Latest

Join the Discussion

After you comment, click Post. If you're not already logged in you will be asked to log in or register with Disqus.